In the demanding field of grain storage, the structural integrity of steel silos is paramount to ensuring safety, longevity, and reliable performance. LIAONING QIUSHI STEEL SILO CO., LTD, a global leader in innovative storage solutions, highlights the critical role of advanced steel structures in withstanding extreme conditions while showcasing its cutting edge engineering technologies that redefine industry standards.

Grain silos face constant stress from heavy loads, environmental factors (wind, snow, seismic activity), and prolonged grain storage. A weak or poorly designed steel structure can lead to deformation, leaks, or even catastrophic failure, resulting in massive grain losses and safety hazards. Studies indicate that 70% of silo failures are directly attributed to inadequate structural support, underscoring the need for robust engineering.

"Steel structures are the backbone of any grain silo," "Our commitment to superior materials and precision engineering ensures that every silo we build stands the test of time and nature."

The company’s steel silos are engineered with a focus on strength, durability, and adaptive design, incorporating three key innovations:

LIAONING QIUSHI uses premium Q355B galvanized steel with a 275g/m² zinc coating, providing 360° corrosion resistance and tensile strength of 355 MPa 30% stronger than standard structural steel. This material choice ensures silos remain intact in harsh environments, from coastal salt exposure to high humidity regions. For example, our silos in Nigeria’s coastal delta have withstood salt-laden air for over 20 years with minimal maintenance.

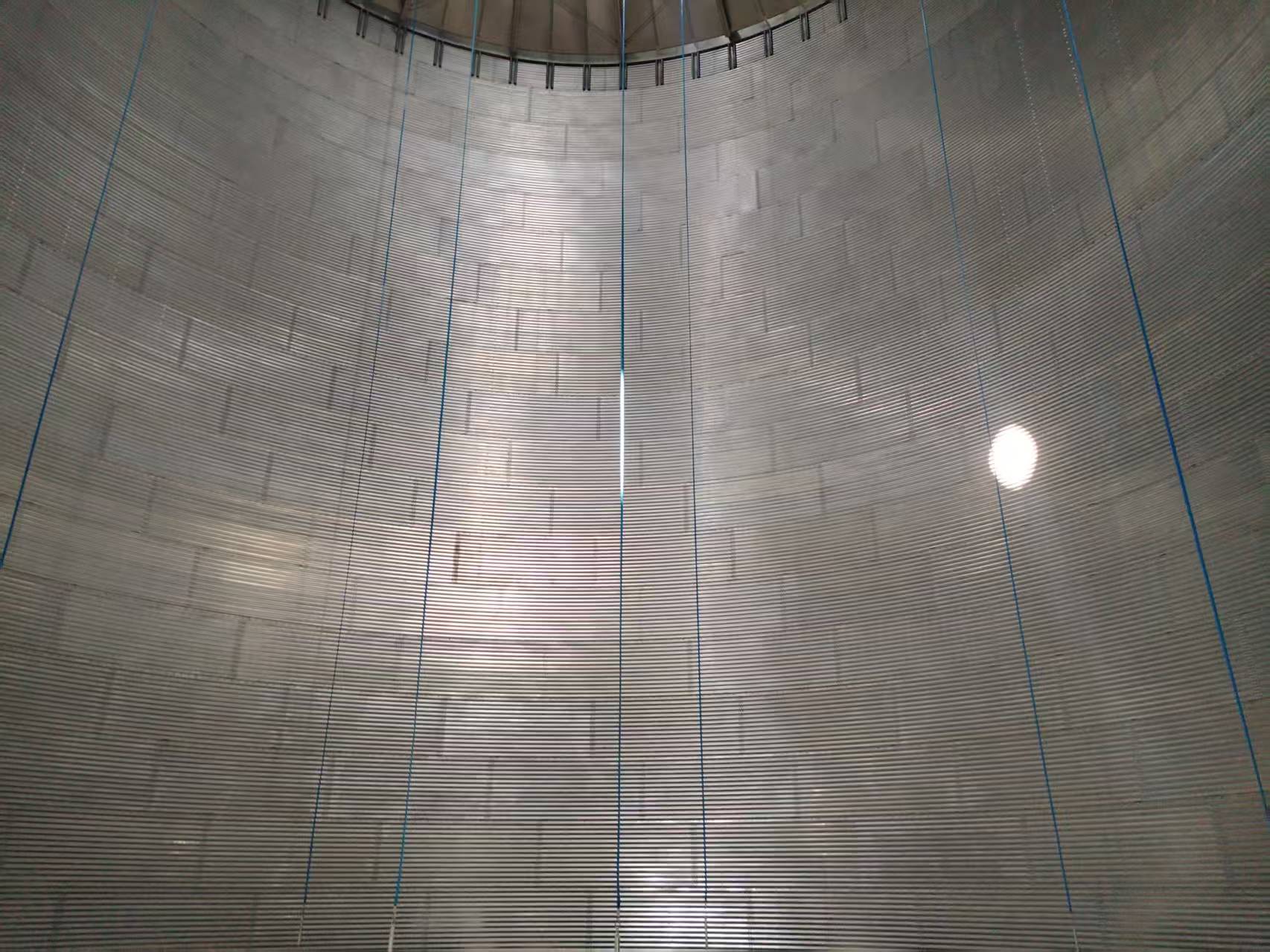

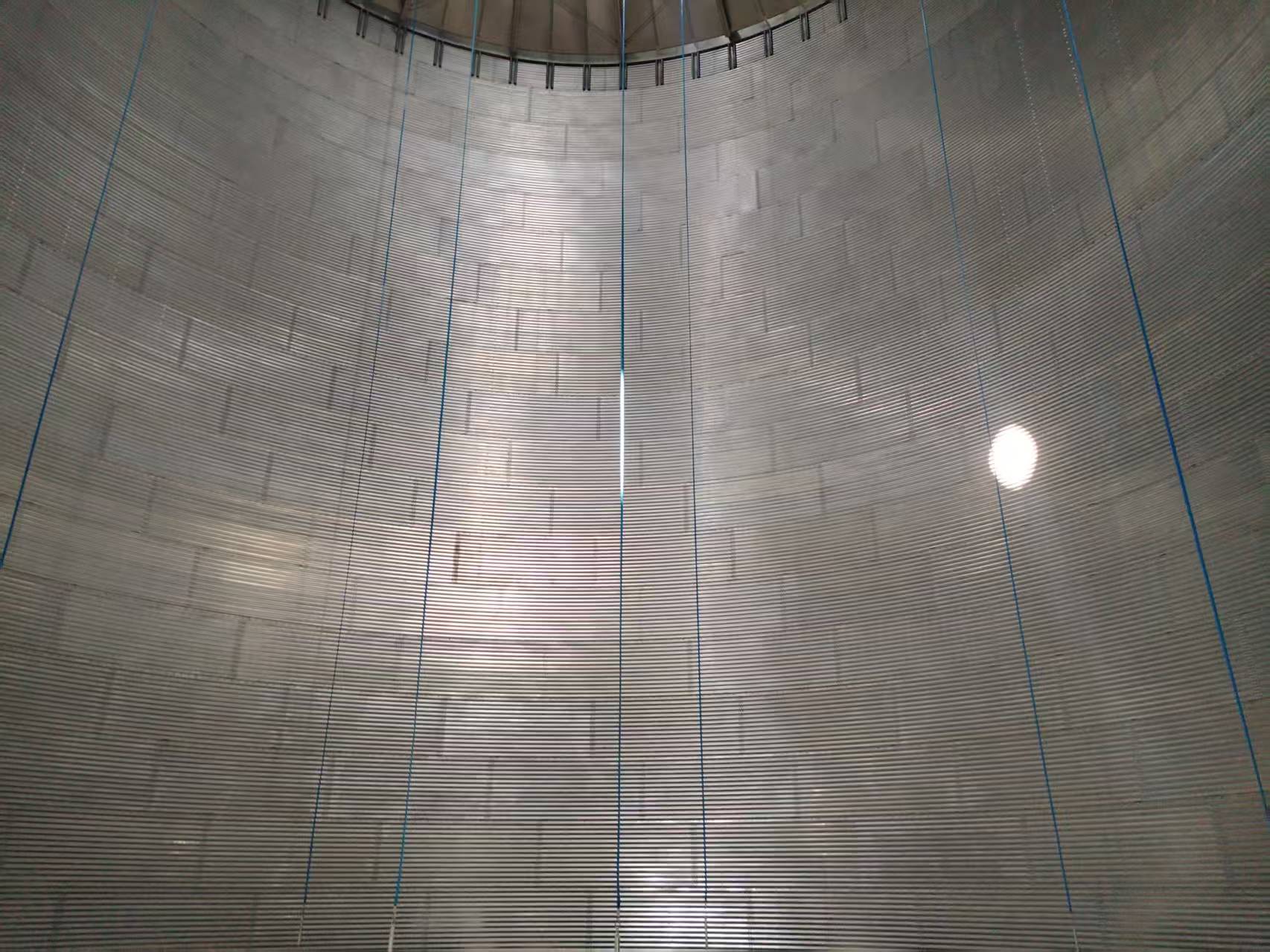

A signature feature of LIAONING QIUSHI’s silos is the continuous spiral welded edge, which thickens the steel by 5 times at critical stress points (e.g., base and roof junctions). This design distributes weight evenly, reducing stress concentrations and enhancing resistance to wind (up to 200 km/h) and seismic activity (up to magnitude 8.0). In Australia’s Outback, our silos withstood a rare category 5 cyclone without structural damage, protecting 5,000 tons of wheat.

The company’s modular bolted steel structures allow for flexible load adjustments. Each section is pre-fabricated with precision-engineered bolts that can withstand up to 800 kN of shear force. This design enables easy expansion (e.g., adding 5,000-ton modules to existing silos) while maintaining structural unity. In Brazil’s Cerrado region, a soybean processor expanded its silo capacity by 30,000 tons using our modular system, ensuring stability under heavy loads.

In Gansu Province, where frequent sandstorms and temperature fluctuations (–30°C to 40°C) challenge storage infrastructure, LIAONING QIUSHI installed a 10,000-ton silo complex with reinforced steel frameworks. Key features included:

Double-layer steel plating at the base to counteract soil erosion

Thermal expansion joints to absorb temperature-induced stress

Aerodynamic roof profiles to reduce wind resistance

After 10 years of operation, annual inspections confirm zero structural defects, with steel integrity remaining at 98% of original standards—far exceeding industry expectations for such harsh climates.

Engineering Precision: Every silo undergoes finite element analysis (FEA) to simulate real-world stresses, ensuring optimal load distribution.

Quality Control: All steel components are tested for hardness (HB 180–210), impact resistance (≥27 J), and dimensional accuracy (±0.5 mm).

Sustainability: 100% recyclable steel reduces environmental impact, with a lifecycle carbon footprint 40% lower than concrete silos.

As global grain storage demands grow, LIAONING QIUSHI continues to innovate. The company’s R&D team is developing AI driven structural health monitoring systems, which use embedded sensors to detect early signs of wear and tear, further enhancing silo safety and longevity.

"Our steel structures are more than just frames—they’re a promise of reliability," "Whether storing 50 tons or 50,000 tons, the LIAONING QIUSHI standard ensures that every silo stands as a testament to engineering excellence."

For technical datasheets or project inquiries, visit www.qssilo.com or contact sales@qssilo.com.

Grain StorageGrain StorageGrain StorageGrain StorageGrain StorageGrain StorageGrain StorageGrain Storage